HTS magnets

Magnetic fields are used in the tokamak to confine and control the electrically-charged ‘plasma’ – the fusion fuel – allowing it to be heated to a temperature above 100 million degrees Celsius. This is the threshold required for fusion to be a commercially viable energy source. Strong magnets in spherical tokamaks enable more compact confinement, increasing plasma density and power.

Strong magnetic fields are generated by passing large electrical currents around arrays of electromagnet coils that circle the plasma. The magnets are wound from ground-breaking high temperature superconducting (HTS) tapes.

Tokamak Energy is a world-leader in the development of HTS magnets for fusion and other applications.

Revolutionary tapes

High Temperature Superconducting (HTS) tapes are innovative high field magnet conductors that make compact fusion possible.

Superconductivity is an ability held by a select group of materials capable of carrying electrical currents with zero electrical resistance. These make for ideal electro-magnet conductors, since they can carry the magnet current without overheating.

For most practical superconductors, this amazing property only works at very low temperatures, around -269°C, with limited magnetic fields. The latest generation ‘high temperature’ superconducting (HTS) tapes exceed these limitations, operating at elevated temperatures with extremely high magnetic fields.

The fusion magnets still need to be cooled to around -250°C, but this is over five times more energy-efficient than the low temperature predecessors.

HTS tapes are multi-layered conductors made mostly of strong and conductive metals, but with a crucial internal coating of ‘rare earth barium copper oxide’ (REBCO) superconducting material. The tapes are typically 12mm wide and less than 0.1 mm thick, containing just a ‘human hair’ of REBCO deposited as a thin coating.

Manufactured commercially by worldwide suppliers in lengths up to 1 km, these incredible conductors can carry 1000s of amperes of electrical current under fusion operational conditions.

When wound into coils, HTS tapes can generate much higher magnetic fields than conventional superconducting magnets, while taking up far less space and requiring far less cooling power.

Efficient magnet powering

One of the main challenges for the magnets is the cryogenic cooling system.

Supplying the magnets with electrical power is a significant load on the cryogenic system. We’ve successfully developed a novel power converter inside a vacuum cryostat that has demonstrated a 50% heat reduction in powering the magnets.

Improving cooling efficiency will reduce costs for future fusion power plants, which is key to commercialising and scaling the technology.

Demo4 magnet system

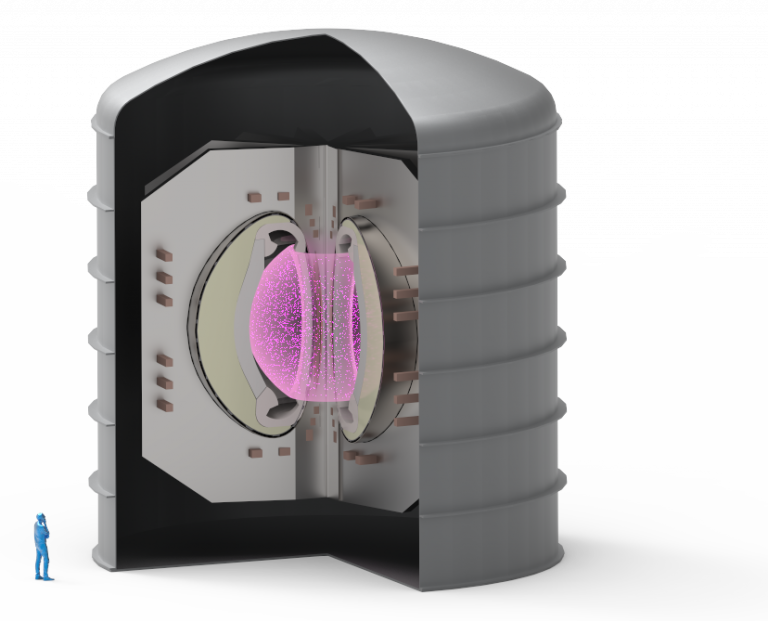

Our ground-breaking Demo4 magnet system is under construction in a purpose-built test facility. Demo4 is a full spherical tokamak magnet set that will substantially progress the technology readiness level of HTS magnets. The design, construction and operation of a high field HTS spherical tokamak magnet is a key step on the road to fusion.

Demo4 is demonstrating the interaction of all the coils and we will show how to control and protect a balanced set of HTS coils in a tokamak configuration.

It will also allow us to create substantial magnetic forces and test them in fusion-relevant scenarios.

The Demo4 system will comprise 14 toroidal field (TF) limbs – which are like segments of an orange – and a pair of poloidal field coils above and below, forming a cage-shaped structure comprised of 44 individual HTS coils.

The system assembly will complete in 2023 and testing will extend into 2024, informing designs for our ST80-HTS advanced prototype fusion machine and future power plant, ST-E1.