Investment & Partnership Opportunities

“Partner with the World’s First Fusion Energy Installation & Integration Company” Join Us

Please see Adobe Secure file links below

Industrial Maintenance Contracting (IMC) is leading the charge in building the infrastructure for commercial fusion energy. Join us in scaling a mission that will reshape the energy sector globally.

My name is Dennis Manning (JR) , I have built IMC alone. I travel all over the US working in many different industrial fields. With a past history of working in the power generation industrial for over a decade and then moving on to Automation Manufacturing, I have slowly worked my way into the fusion energy sector, and have been there every since.

Like My company, This website down to these words you are reding now was all built by my drive and motivation to succeed. I have an opportunity here with my newest client that is achieving new goals and breaking records everyday to be a big part of the fusion industry. I use to travel alone throughout the US and Mexico, and around 5 years ago i started my business and went form an independent contractor to a business owner. Since that time i have been even more invested in everything i do.

I’m looking to be able to grow as my clients are and not have a financial roadblock in the way. When fusion energy becomes a reality, with the knowledge we haev with installing machines and being a par to this industry i think we would be a great fit for assisting with the full on development of building these power plants all over the globe. Our client has got some big partners and they will continue to grow soon to the point of full on fusion energy providing the entire planet with power.

I would like to be the company building those machines as we are now, and with your help we could be. With partnerships, repayment or equity on the line, i am committed to making it happen however i need to.

Between working in the power industry, and the automation manufacturing industry all over the US with hundreds of contractors in various different fields, we have the skills, we are prepared for the travel as its what we do. Competing against Unions and the Financials of scaling will be the only thing slowing us down when the time comes to be installing machines in 5 to 10 different plants across the US simultaneously. Fusion Energy is going to happen, and it is here now.

See below for some details on what we do and what we are looking for. This is not a team of individuals working together to achieve funding for an expansion. It is just me trying to grow my company in a world doing what we are good at. I do have a team of great people that work with me now, that i would like to have be a part of this expansion if we can find the right investors to do so. I’m always available for a call or an email, so please feel free to reach out.

Industrial Maintenance Contracting (IMC)

Building the Future of Fusion Energy

Pitch Deck | July 08, 2025

Vision & Mission

IMC’s vision is to become the world’s first and at this time “ONLY” leading fusion energy installation and integration company, capable of supporting hundreds of commercial fusion power plants across the globe.

Our mission is to deliver expert, scalable, and safety-focused industrial services that accelerate the global deployment of fusion energy.

What We Do

‘ Industrial machine installation, rigging, and commissioning ‘ Fabrication, welding, CNC machining, and millwork

‘ Electrical and mechanical contracting

‘ Contractor recruitment, evaluation, and deployment ‘ Full logistics with in-house trucks and trailers

‘ Nationwide support with crews for multi-shift, 24/7 operations

‘ Fusion technology installation and integration

Why It Matters

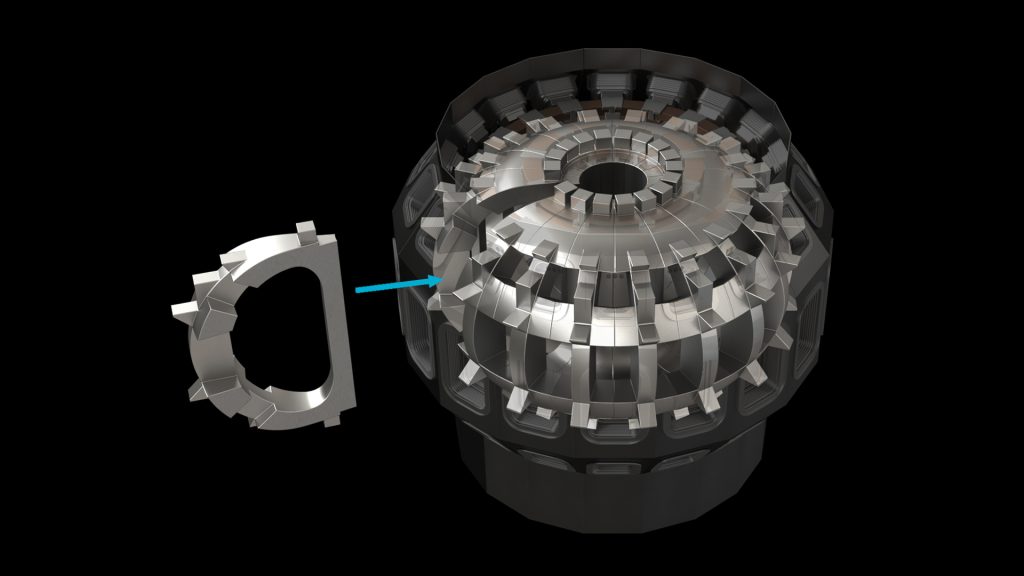

Fusion is the ultimate clean energy solution. With machines delivering 400 megawatts each, commercial fusion is on the cusp of changing the global power landscape.

IMC plays a critical role in making this future possible with having an inside advantage on the US’s first builds, and by providing the manpower, logistics, and integration expertise to install these machines safely and efficiently.

Track Record

‘ Founded in August 2020

‘ Exclusive contractor to Commonwealth Fusion Systems (CFS) for 3 years ‘ Participated in nearly all CFS machine installations to date

‘ ~$3M annual revenue (solely from CFS) ‘ 15 skilled team members and growing

‘ ~$3M annual revenue (solely from CFS) ‘ 15 skilled team members and growing

Solution

We offer:

- Fusion-ready mechanical/electrical install teams

- 24/7 shift-based deployments

- Custom fabrication, wiring, rigging, controls

- Preventive maintenance & zero-downtime protocols

- Contractor-first model = instant scale up or down

The Problem

Fusion energy is real—and scaling fast.

But fusion companies like CFS are outgrowing their contractors.

- No large-scale install teams exist

- Safety risks are high

- Machine installs delay plant builds

- Fusion companies need execution partners, not just vendors

Without us, fusion machine installation growth slows.

Fabrication & Logistics

IMC owns and operates 2 fully equipped fabrication and logistics hubs: ‘ CNCs, mills, paint booths, cranes

‘ Fleet of Company-owned semi-trucks and flatbeds

‘ End-to-end control from fabrication to delivery

‘ Advanced state of the art tooling and equipment, Robotics and automation

Scalable Model

Our contractor-based model allows us to scale rapidly. Whether it’s 1 plant or 50 being built at once, IMC can staff, coordinate, and execute at national and global levels with speed and precision.

💡 Fusion is no longer theory—it’s commercialization.

🌐 Google, Bill Gates, and global funds are backing fusion amongst many others.

📈 100+ commercial plants likely over the next 10–50 years.

IMC is the team positioned to build them.

TAM: $10B+ in industrial contracting for clean energy in the next decade.

The Opportunity

Google has partnered with CFS and purchased the first 200 of a 400 MW plant that will be built in Virginia.

CFS is growing. IMC has the trust and track records.

With investor support, we will scale to meet demand for fusion installations worldwide.

Use of Funds

Capital raised will be used to:

‘ Hire and train 100s of skilled contractors ‘ Expand fabrication capacity

‘ Purchase advanced tooling and vehicles

‘ Build new logistics hubs near fusion plant sites

‘ Invest in technology, tracking, and quality control systems

Founder Background

Dennis Manning, President of IMC

‘ 25+ years in Automation Manufacturing , industrial energy & turbine systems

‘ Veteran of Siemens, Mitsubishi, and Topps Turbine

‘ Built IMC from nothing in 2020 to a multi-million-dollar firm

‘ Passionate about clean energy and building America’s fusion infrastructure

Let’s Build the Future of Energy Together

Contact:

Dennis Manning ‘ President

Email: jrmanning@industrialmco.com Phone: (931) 337-6571

Office solutions@industrialmco.com Phone (704)-856-9494

Website: www.industrialmco.com

WHAT WE DO

Industrial Maintenance Contracting, LLC (IMC) is a specialized contracting company that provides highly skilled contractors for industrial maintenance, machine installation, and operational support to facilities across various high-demand sectors. Operating primarily in industries like manufacturing, energy, infrastructure, and fusion energy integration, IMC is focused on ensuring the reliability, safety, and efficiency of critical industrial operations for its clients.

IMC does not employ traditional full-time employees. Instead, the company contracts skilled professionals on a project basis, deploying them to industrial sites for both short-term and multi-year projects. This contractor-based model allows IMC to flexibly scale operations to meet client needs, supplying expertise in machine installation, mechanical and electrical repairs, equipment inspections, preventative maintenance, and automation systems troubleshooting.

Core Services and Offerings

- Skilled Contractor Provision and Deployment

IMC specializes in sourcing, vetting, and deploying contract-based industrial professionals with expertise tailored to each client’s specific project needs. Each contractor undergoes a rigorous onboarding process, beginning with a 30-day probationary evaluation followed by a provisional employment period, where both IMC and the contractor assess suitability for the long-term project scope. - Safety and Compliance Excellence

IMC prioritizes safety in high-risk environments. All contractors are expected to adhere to OSHA standards, IMC’s stringent PPE requirements, and site-specific safety protocols. Contractors must complete regular safety training and follow procedural documentation, such as Job Safety Analyses (JSA), to maintain a safe work environment. - Project-Based Maintenance and Installation

IMC manages various industrial projects ranging from short-term repairs to long-term maintenance contracts, each requiring customized schedules and specialized skills. IMC’s contractors support critical operations by performing inspections, mechanical and electrical repairs, and predictive maintenance that minimizes downtime and prolongs equipment lifespan. - Flexible Shift Management for 24/7 Coverage

Recognizing the non-standard hours often required in industrial projects, IMC organizes contractors across flexible shift types (such as 5×10, 6×10, or 7×12-hour shifts) to meet client needs. This flexibility enables IMC to offer continuous coverage for essential client operations, adapting to demanding schedules and high project needs. - Performance Monitoring and Project Documentation

To ensure work quality and adherence to client expectations, IMC monitors contractor performance, tracking work progress, quality standards, safety compliance, and punctuality. Performance reviews are conducted regularly, with documented evaluations guiding feedback and potential contract renewals or extensions. - Custom Contracting and Negotiation

Each contractor agreement with IMC is tailored specifically for the contractor’s role, location, and project type. IMC negotiates rate of pay, per-diem, shift expectations, and potential benefits during the onboarding phase, creating a fair, customized arrangement that supports both contractor needs and client project demands.

IMC’s Mission and Strategic Goals

IMC’s mission is to provide expert, reliable industrial support through a dedicated network of contractors who deliver high-quality, compliant, and safety-focused service. By maintaining a large pool of specialized contractors and ensuring strict adherence to safety and quality standards, IMC helps clients minimize operational disruptions and maximize productivity across diverse industries.

Through its contractor-based model, IMC builds lasting partnerships with clients and contractors alike, aligning contractor expertise with client requirements and industry regulations. This strategic approach allows IMC to support complex industrial projects with skilled, adaptable, and safety-conscious professionals—building a trusted name in industrial maintenance contracting across the U.S.

- Flexibility and Adaptability

IMC’s contractor-only model and flexible approach to shift scheduling give it a competitive edge in an industry where project needs are often fluid. This model aligns well with the trend toward more adaptable workforce structures, allowing IMC to scale up or down quickly to match client demand. This flexibility will likely continue to be a strong point as clients increasingly seek partners who can adapt to dynamic schedules and project scopes.

- Commitment to Safety and Compliance

Safety remains a top priority in the industrial sector, especially with heightened regulatory scrutiny and evolving safety standards. IMC’s emphasis on PPE, Job Safety Analyses, OSHA compliance, and ongoing safety training addresses this need head-on. The company’s commitment to a proactive safety culture positions IMC as a reliable and responsible choice for clients, especially those in high-risk industries. As safety regulations continue to advance, this strong foundation in compliance will be essential.

- Emphasis on Specialized Expertise

With many industries facing skilled labor shortages, especially in technical and specialized roles, IMC’s focus on highly skilled contractors is an asset. By offering vetted experts in installation, maintenance, and repair, IMC provides clients with the niche expertise they might struggle to find independently. This focus on specialization can continue to drive IMC’s success, as companies increasingly seek targeted expertise rather than generalist solutions.

- Client-Centric Customization

IMC’s approach to contract negotiation, project-specific customization, and contractor alignment with client standards is a significant advantage. Tailoring services to each client’s unique project requirements reflect a client-first philosophy, which is crucial as companies look for contracting partners who prioritize efficiency, safety, and results. This ability to customize and negotiate ensures that IMC remains flexible enough to meet diverse client needs over the long term.

- Adapting to Workforce Trends

Today’s workforce, especially in skilled trades, increasingly values contract-based work and flexibility. IMC’s mission aligns with this trend by offering contractors autonomy, negotiable benefits, and tailored contracts while preserving a high standard of accountability and professionalism. IMC’s approach to individual contract customization, including benefits for long-term contractors, helps the company attract and retain skilled professionals.

- Futureproofing Through Digital Integration and Documentation

IMC’s commitment to structured documentation (such as JSAs, Service Trackers, and daily logs) also strengthens its mission’s longevity. As digital tools continue to become more integrated into industrial workflows, IMC’s existing focus on meticulous documentation and performance tracking positions it well to incorporate future technologies. By embracing digital transformation, IMC can streamline operations further, reducing administrative burdens and increasing accountability.

Challenges and Considerations

IMC may face challenges as it grows, especially as expectations for sustainable practices, automation, and technological proficiency become more prevalent. However, with its adaptable contractor model and focus on skill specialization, IMC can continue evolving in response to these changes. Incorporating digital solutions, staying ahead of industry certifications, and maintaining a strong safety record will be essential to upholding its mission.

Conclusion

IMC’s mission of providing skilled, reliable, and flexible contracting solutions for industrial maintenance aligns with current and anticipated industry trends. By upholding its commitment to safety, adaptability, and high-quality service, IMC is well-equipped to navigate both today’s challenges and future demands, standing out as a resilient and dependable industrial partner.